MIL-PRF-83531C

maximum.

4.5.2 Group A inspection

4.5.2.1 "C" screening level PIN. The manufacturer shall establish and maintain an inspection system

to verify that delay lines meet the electrical, visual, mechanical, and solderability requirements. In-line or

process controls may be part of such a system. The inspection system shall include criteria for lot

rejection and corrective action. The inspection system shall be verified under the overall QPL system

(see 3.3). NOTE: Since the "C" level delay line is the same design as the "M" level without the

mandatory conformance inspection system, this product is still expected to meet the environmental

qualification type requirements (moisture resistance, shock, or vibration) (see 4.5.3.4).

4.5.2.2 "M" screening level PIN. Group A inspection shall consist of the inspections specified in

table II, in the order shown.

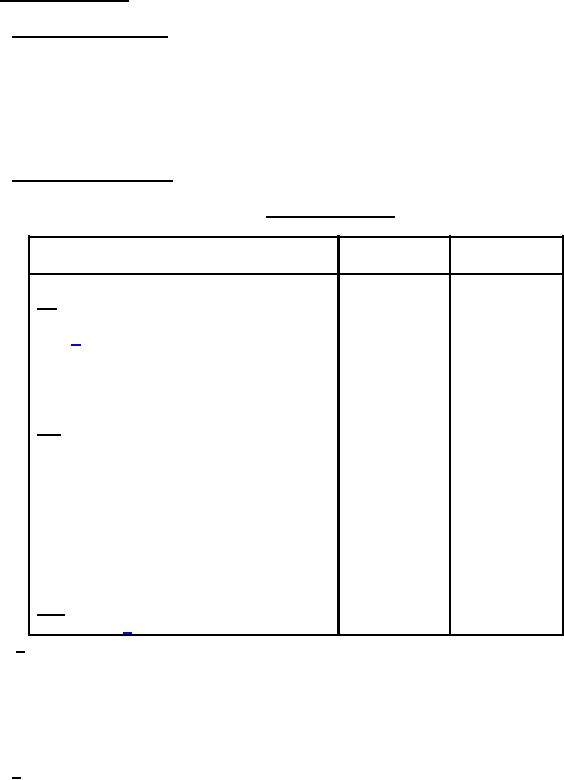

TABLE II. Group A inspection.

Inspection

Requirement

Test method

paragraph

paragraph

A-I

4.6.4

Thermal shock (15 cycles)

3.6

4.6.5

Seal 1/

3.7

4.6.6.1.1

Delay time(all taps and output)

3.8.1

4.6.6.1.2

Rise time (output only)

3.8.2

4.6.6.1.8

Insulation resistance

3.8.8

A-II

4.6.2

Dimensions

3.5.1

4.6.3

Visual inspection

3.5.2

4.6.6.1.6

DC resistance

3.8.6

4.6.6.1.3

Voltage attenuation (output only)

3.8.3

4.6.6.1.4

Distortion (output only)

3.8.4

4.6.6.1.7

Nominal characteristic impedance (at input)

3.8.7

Delay time variation with temperature

4.6.6.1.5

(output only)

3.8.5

A-III

4.6.8

Solderability 2/

3.10

1/ This seal test can be eliminated for plastic injection molded cases if the manufacturer has

demonstrated process control under the SPC program (see 3.3.1), or other method that has

been approved by the qualifying activity. If the design, material, technology, or processing of

the part is changed or, if there are any quality problems, or failures, the qualifying activity

may require resumption of the specified testing. Deletion of testing does not relieve the

manufacturer from meeting the test requirement in case of dispute.

2/ This solderability test can be eliminated if the manufacturer has demonstrated process

control under the SPC program (see 3.3.1), or other method that has been approved by the

qualifying activity. If the design, material, technology, or processing of the part is changed

11

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business