MIL-PRF-83531C

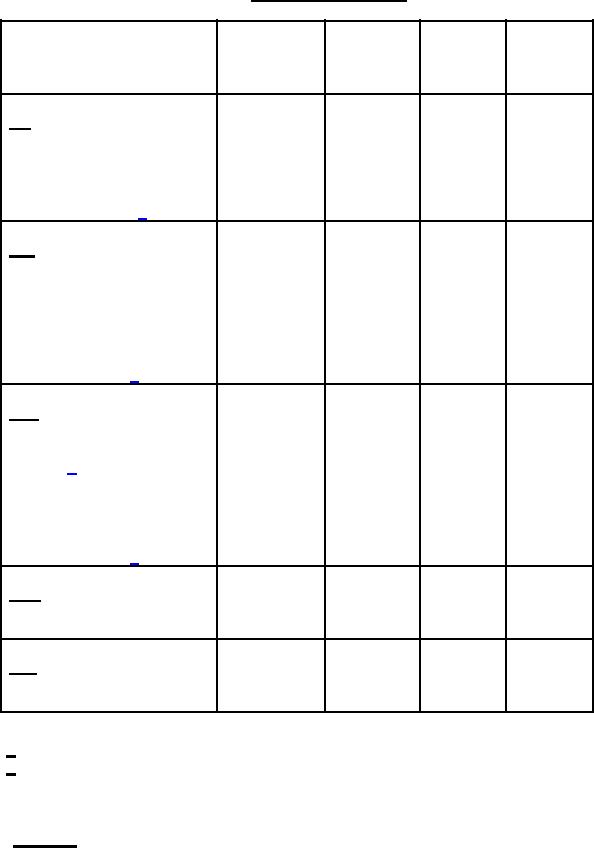

TABLE I. Qualification inspection.

Inspection

Requirement

Test

Number of

Number of

paragraph

method

sample

allowable

paragraph

units

failures

Q-I

Dimensions

3.5.1

4.6.2

Thermal shock (50 cycles)

3.6

4.6.4

22

2

Seal

3.7

4.6.5

Electrical characteristics

3.8

4.6.6

Visual inspections 1/

3.5.2

4.6.3

Q-II

Moisture resistance

3.11

4.6.9

Salt spray (corrosion)

3.12

4.6.10

6

0

(metal cases only)

Vibration

3.13

4.6.11

Shock

3.14

4.6.12

Electrical characteristics

3.8

4.6.6

Visual inspection 1/

3.5.2

4.6.3

Q-III

Life

3.15

4.6.13

Terminal strength

3.16

4.6.14

Fungus 2/

3.17

4.6.15

Electrical characteristics

3.8

4.6.6

6

0

Dielectric withstanding

3.18

4.6.16

voltage at reduced

barometric pressure

Visual inspection 1/

3.5.2

4.6.3

Q-IV

Resistance to soldering heat

3.19

4.6.17

4

0

Flammability

3.20

4.6.18

Q-V

Resistance to solvents

3.9

4.6.7

4

0

Solderability

3.10

4.6.8

1/ The "JAN" or "J" marking and PIN are not required on qualification samples.

2/ The fungus test shall not be performed if the manufacturer provides certification that all

external materials are non-nutrient to fungus growth or suitably treated to retard fungus

growth.

3.4.5.2 Meniscus. Terminals shall be free of case meniscus or other foreign material and shall be

solderable for a minimum of .010 inch (0.25 mm) above the seating plane of the delay line.

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business