MIL-DTL-55422B

3.2 Material. The material for each part shall be as specified (see 3.1). When a definite material is not specified,

a material that will enable the clips to meet the requirements of this specification shall be used. Acceptance or

approval of a constituent material shall not be construed as a guarantee of the acceptance of the finished product.

Materials shall be non-nutrient to fungus growth. Submission of certification that materials used are noon-nutrient to

fungus growth will be considered compliance with this requirement without testing. If certification is not furnished,

clips shall be subjected to the fungus-resistance test of method 508, procedure I, of MIL-STD-810.

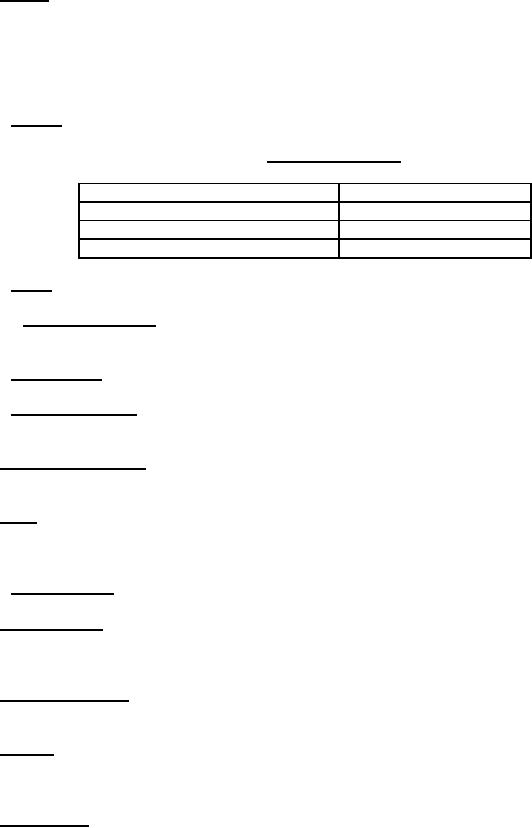

3.2.1 Ceramic. Ceramic material shall conform to requirements in table I or better.

TABLE I. Ceramic requirements.

Dielectric constant

12 or under

Dielectric loss index at 1 MHz

.016 maximum

Dielectric strength average

200 to 249, inclusive

Flexural strength (modulus of rupture)

12,000 to 19,000 inclusive

3.2.2 Metals.

3.2.2.1 Beryllium-copper alloy. Beryllium-copper alloy shall conform to ASTM B194 and shall be suitably heat

treated after forming and prior to cleaning and plating.

3.2.3 Silicone rubber. Silicone rubber shall conform to class 3B of A-A-59588.

3.2.4 Corrosion-resistance. The clips shall be fabricated of a corrosion-resistant material or be treated to prevent

corrosion formation.

3.3 Design and construction. The clips shall be of the material, design, construction, and physical dimensions

specified (see 3.1).

3.4 Finish. Finish shall be electro-tin plate as specified in ASTM B545. The clips shall be plated so that before

and after the environmental tests specified herein, there shall be evidence of peeling, cracking, or corrosion. Unless

specifically approved by the acquiring activity, no additional insulating material shall be applied.

3.4.1 Cadmium plating. Cadmium plating shall conform to class 2, type II of SAE AMS QQ-P-416.

3.5 Dissimilar metals. When dissimilar metals are used in intimate contact with each other, protection against

electrolysis and corrosion shall be provided. The use of dissimilar metals which, in contact, tend toward active

electrolytic corrosion (particularly brass, copper, or steel used in metals) shall be as specified in MIL-STD-889.

3.6 Salt spray (corrosion). When clips are tested as specified in 4.5.2.1, the base metal shall show no evidence

of corrosion on blistering of plated surfaces.

3.7 Vibration. When tested as specified in 4.5.2.2, the clip shall display no evidence of cracking, breaking,

loosening of parts, wear or damage to the clip, nor loss of electrical continuity of the contact circuit for a period

greater than 10 microseconds.

3.8 Thermal shock. When tested as specified in 4.5.2.3, the clip shall retain a force on the test plug of not less

than 80 percent as measured before the test. There shall be no cracking or chipping of the ceramic insulated clips.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business