MIL-DTL-55422B

4.3 Inspection conditions. Unless otherwise specified herein, test conditions shall be as specified in

4.4 Conformance inspection.

4.4.1 In-process inspection. Inspection of product for delivery shall consist of groups A and B. Sampling plans

and procedures for inspection shall be as specified in table III.

4.4.1.1 Inspection lot. An inspection lot shall consist of all the clips of the same material, configuration, and

dimensions, manufactured under essentially the same conditions and submitted for conformance inspection and

testing at one time.

4.4.1.2 Rejected lots. If an inspection lot is rejected, the supplier may withdraw the lot, rework it to correct the

defects, or screen out defective units, as applicable, and reinspect. Such lots shall be separated from new lots and

shall be clearly identified as reinspected lots. Rejected lots shall be inspected using tightened inspection.

4.4.1 3 Group A. inspection. Group A inspection shall consist of the inspections in 4.5.1 with the sample sizes of

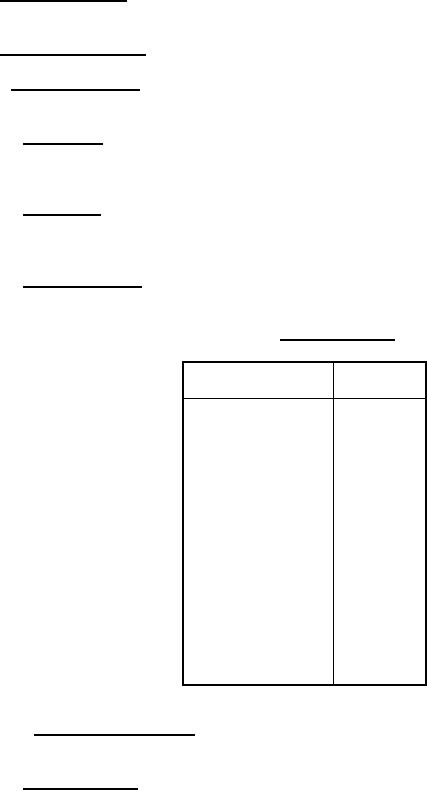

TABLE III. Group A inspection.

Lot size

Inspection

of product

2 to

8

100 percent

9 to

15

13

16 to

25

13

26 to

50

13

51 to

90

13

91 to

150

13

151 to

280

20

281 to

500

29

501 to 1,200

34

1,201 to 3,200

42

3,201 to 10,000

50

10,001 to 35,000

60

35.001 to 150,000

74

150,001 to 500,000

90

500,000 and over

102

4.4.1.3.1 Disposition of sample units Sample units which have been subjected to group A inspection shall be

delivered on the contract or order.

4.4.1.4 Group B inspection. Group B inspection shall consist of the tests specified in table IV in the order shown.

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business